NASA scientists are making strides towards creating an innovative battery pack that is lighter, safer, and performs better than batteries currently used in vehicles and big electronics. As part of NASA’s efforts to promote sustainable aviation, their research into solid-state batteries for aviation uses like electric propelled aircraft and Advanced Air Mobility aims to advance battery technology.

Solid-state Architecture Batteries for Enhanced Rechargeability and Safety (SABERS)

After several years of successful work by a NASA programme known as SABERS, the research has piqued the interest of government, industry, and academics. Solid-state batteries, unlike industry-standard lithium-ion batteries, do not contain liquids, which can cause harmful conditions such as overheating, fire, and loss of charge over time—issues that anyone who uses big devices may be familiar with. Solid-state batteries don’t have to deal with these dangerous situations, and they can store more energy and work better under stress than regular lithium-ion batteries.

To strengthen the battery, SABERS researchers worked with a variety of organizations and other NASA Aeronautics projects. “SABERS continues to outperform its targets,” said Rocco Viggiano, SABERS chief investigator at NASA’s Glenn Research Center in Cleveland. “We are beginning to approach this new frontier of battery research that could do so much more than lithium-ion batteries can.” “The possibilities are pretty amazing.”

Recent Developments

When making electric planes that are better for the environment, it’s important to think about how well the batteries work. These batteries must be able to store the huge amount of energy that is needed to power an airplane while still being light, which is a very important requirement in aviation. The quantity of energy a battery can store, however, is only one aspect of the equation. A battery must also discharge this energy quickly enough to power big electronics like an electric aircraft or unmanned aerial vehicle. In other words, a battery can be compared to a container. The energy (or capacity) of a battery is how much the bucket can store, whereas its power is how quickly the bucket can be emptied. The battery must discharge its energy, or empty its bucket, at an extremely fast rate to power an electric airplane.

To do this, SABERS has tried out new materials that have never been used in batteries before. This has led to big improvements in the way power is released. In the past year, the team increased the discharge rate of their battery by a factor of ten, then by a factor of five. This got them closer to their goal of powering a large vehicle.

Possibility of Design Variations

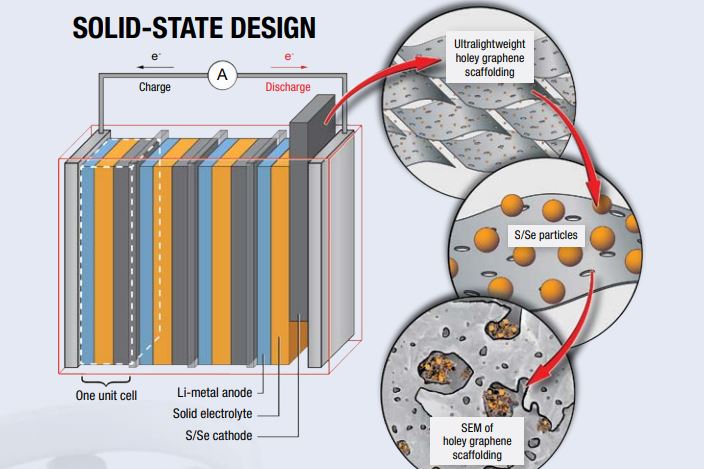

The SABERS team realized that solid-state architecture enabled them to change the construction and packaging of their battery to save weight while increasing the amount of energy it can store—the size of the bucket from the previous analogy. Instead of housing each individual battery cell inside its own steel casing, as liquid batteries do, SABERS’ batteries can be piled vertically inside a single casing. SABERS has demonstrated solid-state batteries can power objects at a massive capacity of 500 watt-hours per kilograms, which is double that of an electric vehicle, thanks in part to this novel design.

Viggiano said, “Not only does this design cut 30–40% of the battery’s weight, but it also lets us double or even triple the amount of energy it can store, which is much more than lithium-ion batteries, which are considered state-of-the-art.”

Another critical prerequisite for the use of batteries in electric aircraft is safety. Solid-state batteries, unlike liquid batteries, do not catch fire when they malfunction and can continue to work even when damaged, making them appealing for use in aviation.

Researchers at SABERS tested their battery under various pressures and temperatures and discovered that it can work in temperatures nearly twice as hot as lithium-ion batteries, despite the lack of cooling technology. The crew is still testing it in even hotter conditions.

Future Deals

The main goal for SABERS this year was to show that the battery’s properties meet its energy and safety goals and that it can work safely at full power and in real-world conditions. SABERS has worked with a number of partners on this cutting-edge study, including Georgia Tech, Argonne National Laboratory, and the Pacific Northwest National Laboratory. For example, the partnership with Georgia Tech enabled researchers to use various methodologies in their work and find ways to improve their battery for practical use.

Georgia Tech places a strong emphasis on the micromechanics of how the cell changes during function. “This allowed us to examine the pressures inside the battery, which allowed us to enhance the battery even further,” said Viggiano. “It also led us to understand how to manufacture a cell like this from a practical standpoint, and it led us to some other improved design configurations.”

SABERS has also used the expertise of several NASA centres and projects to accomplish its goals. “We have had a lot of fruitful conversations about how others at NASA could leverage our work and potentially use our battery,” Viggiano said. “It has been incredibly rewarding to consider what might come of it. “We have seen SABERS develop from a lunchtime idea to a potential energy solution for aeronautics.”

SABERS is part of the Convergent Aeronautics Solutions project, which is meant to give NASA researchers the tools they need to figure out if their ideas for solving some of aviation’s most difficult technical problems are possible and, if so, if they should be looked into further by NASA or the private sector.

Leave A Comment