Aluminum-air batteries are a type of metal-air battery that use aluminum as the anode and oxygen from the air as the cathode. They have a high energy density, which means they can store a lot of energy in a small space, making them useful for portable applications such as electric vehicles and portable electronics.

Here are some key points about aluminum-air batteries:

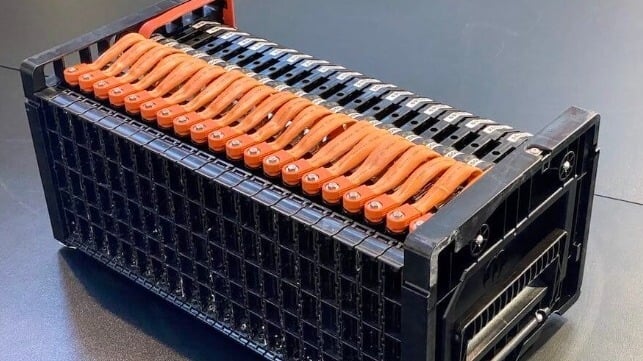

How they work: Aluminum reacts with oxygen from the air to form aluminum oxide and release energy in the form of electricity. This reaction occurs in a porous carbon electrode, which allows air to flow through and react with the aluminum. The reaction produces aluminum hydroxide, which can be recycled back into aluminum oxide through a chemical process.

Advantages: Aluminum-air batteries have a very high energy density, which means they can store a lot of energy in a small space. They are also relatively cheap and abundant, as aluminum is the most abundant metal in the Earth’s crust. Additionally, they have a long shelf life, as they do not self-discharge like some other types of batteries.

Additionally, it is less susceptible to extreme heat, making it safer and better adapted to Indian climate conditions. In light of India’s growing adoption of electric vehicles, which has been boosted by government initiatives like FAME, ACC PLI, Auto & Auto Components PLI, etc., this solution could contribute to reducing dependence on imports.

A value chain for the manufacturing, transportation, and recycling of aluminum as a metal has been in place for more than a century. The use of aluminum as an energy carrier has the potential to upend India’s e-mobility industry due to the wealth of domestic aluminum and the country’s well-established aluminum industry.

Disadvantages: Aluminum-air batteries have a limited lifespan because the aluminum anode is consumed in the reaction with oxygen. They also have a lower power density than some other types of batteries, which means they cannot discharge energy as quickly. Finally, they require a steady supply of air to function, which can be a problem in certain environments.

Applications: Aluminum-air batteries are being researched for use in electric vehicles, where their high energy density could make them a competitive alternative to lithium-ion batteries. They are also being developed for use in portable electronics and grid-scale energy storage.

Challenges: One of the biggest challenges facing aluminum-air batteries is the need to develop a stable and efficient cathode material. Oxygen from the air can react with a variety of different metals, but finding one that is both stable and efficient has proven difficult. Additionally, the reaction between aluminum and oxygen can produce heat, which can cause the battery to overheat and fail.

Recent Developments in India

Hindalco Industries Limited, the metals division of the Aditya Birla Group, has signed a memorandum of understanding (MoU) with Phinergy, a well-known Israel-based pioneer in metal-air battery technology, and IOC Phinergy Private Limited (IOP), a joint venture between Phinergy and Indian Oil Corporation, the country’s largest energy PSU. The Memorandum of Understanding states that Phinergy and IOP will work in exclusive partnership with Hindalco in India on research and development as well as trial production of aluminum plates for Aluminium-Air batteries and recycling of aluminum after it has been used in these batteries.

At the Auto Expo 2023, which was held in Greater Noida, IOP displayed its first ever complete ecosystem for Aluminum-Air energy in India. This ecosystem included R&D, manufacturing, and associated services. IOP displayed India’s very first electric vehicle as well as India’s very first electric rickshaw, both of which were powered by an aluminum-air system.

Leave A Comment