According to a report by McKinsey, shortages of critical battery raw materials, including lithium, nickel, cobalt, and copper, will be a significant obstacle to plans for the global adoption of electric vehicles for the energy transition to reduce carbon emissions. In a briefing note on “sustainable and inclusive growth,” experts from McKinsey say that market disruptions caused by the Russian invasion of Ukraine and years of underinvestment in the mining sector have caused spot prices for battery-grade lithium to rise by more than 400% year over year since July 2022, while nickel prices have risen by more than 100% during the same time period.

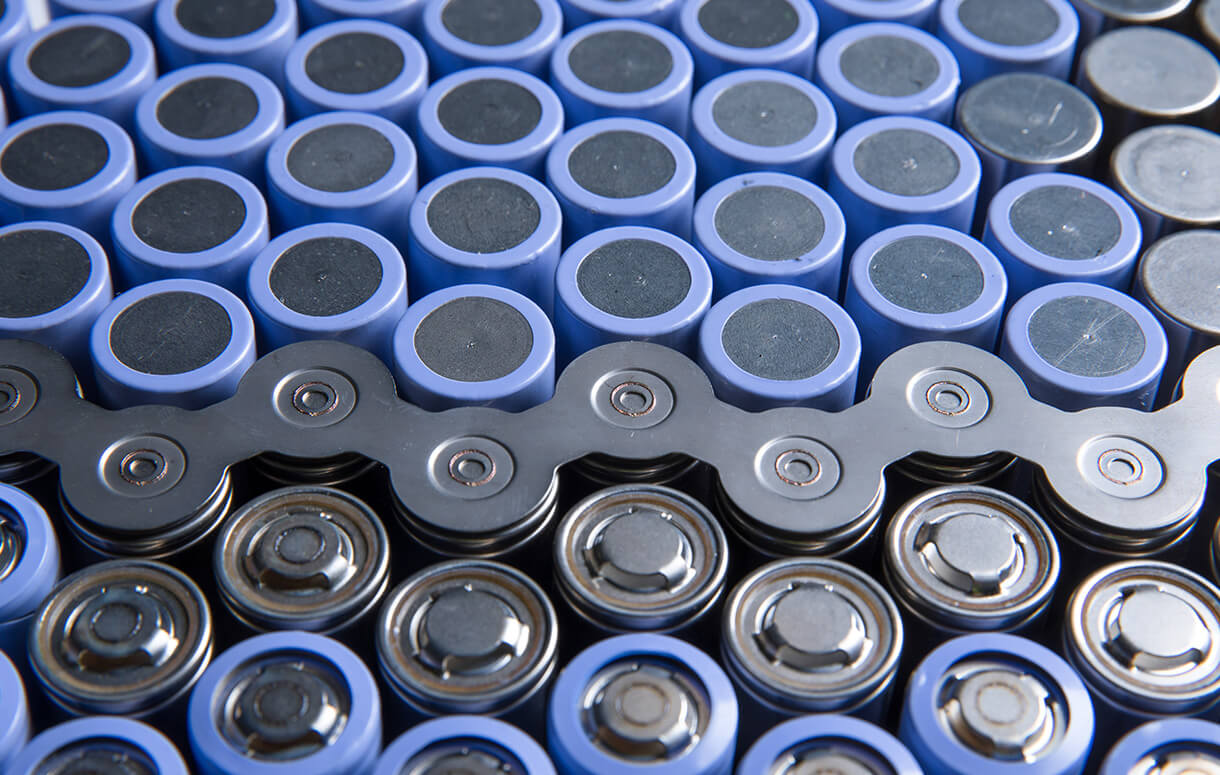

McKinsey predicts that by 2030, depending on how aggressively CO2-emission reduction targets are pursued, EV sales in the US will increase from their current low of less than 5% of sales to between 29 and 59%. Original equipment manufacturers (OEMs) expect at least 40% of unit sales to be electric by 2035, which is also when six states in the U.S. have said they will switch to all-electric transportation. Lithium is used in all cathode chemistries in batteries (and potentially next-generation anodes). Certain cathode chemistries use nickel and cobalt, and copper is used in motor windings and rotors. Currently, these components make up around 50% of a battery’s overall price.

“However, success will also need these materials to be available in considerably larger quantities than they are at present and at a lower cost, which is currently improbable,” say McKinsey’s experts. “Accelerating EV penetration is focused mainly on cutting other battery-making costs.”

Depending on the mineral, EV forecasts show that demand for these minerals will increase from two to twelve times current levels by 2030, with lithium experiencing the highest growth rate. According to McKinsey, the “Fading Momentum” scenario (slower adoption of EVs, less plastic recycling or avoidance due to technology and supply delays, and lax enforcement of regulations) would require a gap between the supply and demand of materials of between 3.7 and 5.2 million metric tonnes (Mt) by 2030 in order to achieve 29% of new car sales.

While there is a greater chance that measures will be taken to assist in reducing the supply-demand gap for lithium, copper, and cobalt, the industry will likely struggle to do so for nickel, which faces a shortfall of about 0.6 to 1.1 Mt. Experts from McKinsey say that in order to meet this demand, the industry may have to lower the performance of EVs by using cathodes with less nickel that have a lower energy density or quickly build mines that aren’t as profitable but will make money if nickel prices stay high.

According to recent IEA research, China processes 58% of the world’s lithium, followed by Chile (29%), and Argentina (10%).China holds a 65% share of the global cobalt market, followed by Finland (10%) and Belgium (5%). The two most important raw materials for renewable energy solutions, nickel and copper, are processed to a high degree in China. It processes 35% of the world’s nickel, followed by Indonesia (15%) and Japan (8%). China is responsible for 40% of the processing of copper, followed by Chile (10%) and Japan (6%). However, many of these vital raw materials are not primarily produced in China. In the instance of lithium, while China holds a 58% worldwide processing market share, Australia holds a 52% share of the top producing nations for the extraction of this crucial raw material, followed by Chile (22%), and China (13%). The Democratic Republic of the Congo (DRC) accounts for about 69% of the world’s cobalt extraction, with Russia and Australia capturing the remaining 4%. With a 33% market share, Indonesia is the top nickel extractor, followed by the Philippines (12%) and Russia (11%). Following Chile with a 28% extraction rate of copper are Peru with 12% and China with 8%.

Leave A Comment