LFP Batteries?

Similar to other batteries, Lithium Iron Phosphate (LiFePO4) batteries have an anode, cathode (LiFePO4), separator, electrolyte, and positive and negative current collectors. The positive and negative terminals of the battery are termed as the cathode and the anode respectively. The lithium ions originated from the anode moves towards the cathode using electrolyte as a carrier and vice-versa through the separator. The free electrons, created as a result of lithium ions’ movement, flow towards the cathode through an external circuit. This leads to the flow of current from the positive terminal to the negative terminal when an electric load is connected across the battery.

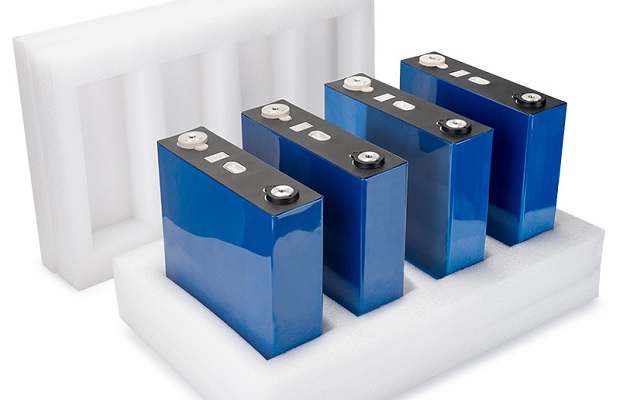

Schematics of a LFP battery.

Source: Rebelbatteries

The cathode material LFP (LiFePO4), in these batteries, is a polyanion (more than one negatively charged element) and with crystalline arrangement of atoms forming a 3D network of lithium ions. While there are 2D slabs in the nickel manganese cobalt arrangement. Additionally, phosphate is a non-toxic material when compared to cobalt oxide or manganese oxide.

Advantages of LFP over Li-Ion batteries

Despite having lower energy density than those of Li-ion batteries, LFP offers certain crucial advantages over Li-ion batteries. These advantages are:

Longer Life Cycle

One of the important advantages that LFP offers over Li-ion is its life cycle. A LFP can last for 2000-7000 charge and discharge cycles while on the other hand a Li-ion has 200-500 cycles. LFPs can handle high temperatures with minimum degradation.

Safe and Stable Chemistry

LFP offers better thermal and structural stability as compared to any other battery. Basically, LFP is incombustible and stays cool in higher temperatures. These batteries are proven to be safe when mishandled during rapid charges and discharges or when there is a short circuit. These batteries rarely experience thermal runaway because phosphate cathodes are very hard to ignite during overcharging.

Easier Disposal and Cheaper

LFP is non toxic in nature and can be easily disposed of. On the other hand a lithium-ion battery with a lithium cobalt dioxide chemistry is a hazardous material and can cause allergic reactions to the eyes and skin when exposed. So, special disposal considerations must be made for lithium-ion which in turn adds to the overall cost. Thus, LFP batteries are relatively cheaper as the manufacturers don’t have to spend more money to recycle the material.

Obstacles in Wide Scale LFP Usage

The energy density of is lower than those of alternatives approximately by 20 to 25%. Which is a key factor that has been hindering their wide scale usage all this while. However, by recent research this factor can be overcome by making thicker electrodes. This was done in Shanghai-made Model 3, delivering an energy density of 359Wh/liters. China has the most number of LFP patents and thus is a leader in the LFP market. There is a probability that once these patents expire LFP production will be localized. This factor is also acting as one of the obstacles.

For a specific voltage more LFP batteries are needed because their per cell voltage is lower than Li-ion batteries. Thus, LFPs are not a one-size-fits-all solution and may not be as useful in heavy vehicles. Additionally, because of their low energy density these battery packs are relatively heavier and bigger than other alternatives.

Overall, the LFP phenomenon in the EV industry has attracted the manufacturer towards itself owing to lower costs and environmental safety. In addition to that Elon Musk’s reliance on these batteries has encouraged other manufacturers to go along in the same direction. For now, predictions are only pointing towards a fair increase in share of LFP batteries in EVs in the upcoming years. LFP batteries and their advantages could be fundamental to the mass EV adoption in the near future. Apart from Tesla, EV manufacturers like VW, Ford, Hyundai and Rivian have hinted at using LFP in near future.

Leave A Comment