The battery life of electric cars can be extended by up to 15 years thanks to a novel polymer coating developed by experts at Lawrence Berkeley National Laboratory.

For the transportation industry to become carbon-free and for net-zero objectives to be achieved, the widespread adoption of electric vehicles (EVs) is required worldwide.

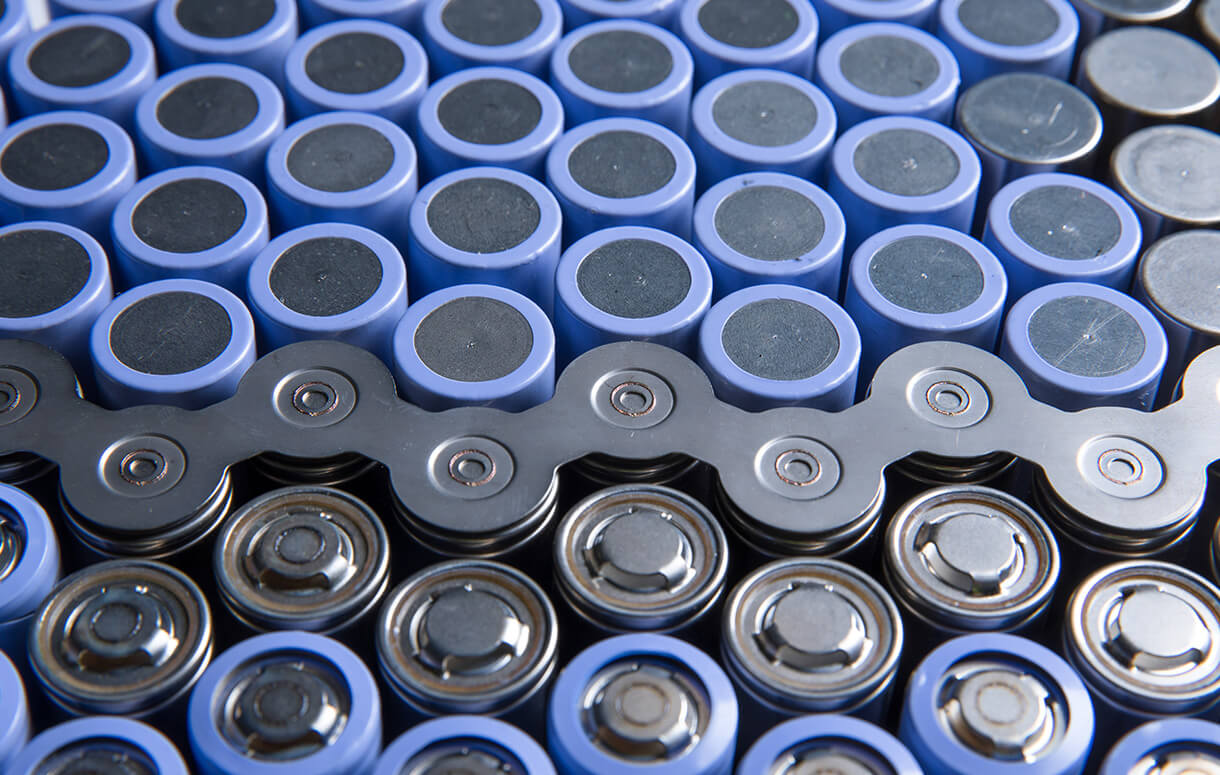

At the moment, the technology is limited by the fact that the batteries don’t last long enough and don’t give enough driving range. Researchers have made a polymer coating called HOS-PFM that, when put on the batteries of electric vehicles, increases both the power output and the batteries’ lifespan. This could be a game-changing solution to these problems.

According to Gao Liu, a senior scientist in the Energy Technologies Area, the discovery “opens up a new approach to developing EV batteries that are more affordable and simple to manufacture.”

The research paper titled “Formation of hierarchically ordered structures in conductive polymers to improve the performance of lithium-ion batteries” has the potential to be a significant tipping point for the field of electric mobility.

What is the working principle behind the innovative polymer coating?

The HOS-PFM polymer coating extends the life of the battery by simultaneously conducting electrons and ions. This not only ensures the reliability of the battery for electric vehicles but also allows for high charge and discharge rates.

The battery adhesive HOS-PFM has also shown that it might be able to make lithium-ion batteries last 10–15 years longer.

The researchers applied the polymer coating to silicon and aluminum electrodes and then tested the performance of the electrodes on a setup similar to that of a lithium-ion battery in order to demonstrate the conductive and adhesive properties of the HOS-exceptional PFM.

Silicon and aluminum are two potential candidates for use as electrode materials in lithium-ion batteries due to their large energy storage capacities, widespread availability, low weights, and low prices. However, after being subjected to a significant number of charge and discharge cycles, these materials begin to deteriorate.

The findings of the study conducted by the researchers demonstrated that HOS-PFM prevents the breakdown of electrodes based on silicon and aluminum when batteries are changed.

In addition, the covering enabled the battery to have a high capacity of over 300 cycles, which is roughly equivalent to the performance of the most cutting-edge electrodes that are currently available on the market.

Liu came to the conclusion that the findings were remarkable despite the fact that silicon-based lithium-ion cells typically only have a limited capacity for charge and discharge cycles as well as a finite lifespan.

It is possible that the HOS-PFM covering will make it possible to use conductors that contain up to 80% silicon. As a consequence of the high silicon concentration, lithium-ion batteries may experience an increase in their energy density of at least thirty percent.

Since silicon is cheaper than graphite, which is the current industry standard for electrode materials, making cheap batteries could make it possible to make a lot of electric cars with lower starting prices.

There is a growing demand for electric vehicles as a result of the impending ban on the sale of new gasoline and diesel-powered vehicles in important automotive producing nations such as the United States and the United Kingdom beginning in 2035.

However, many aspects of the technology will need to be refined before electric vehicles can win over the hearts and minds of motorists all over the globe. This involves the infrastructure for charging electric vehicles, their range, and how long their batteries last.

At the moment, the average range of an electric car is between 240 and 500 miles, and its lifespan is about 15 to 20 years. These capabilities, which currently fall short of those of conventional vehicles, need to be enhanced in the years to come in order to hasten the transition to electrically powered modes of transportation.

Leave A Comment